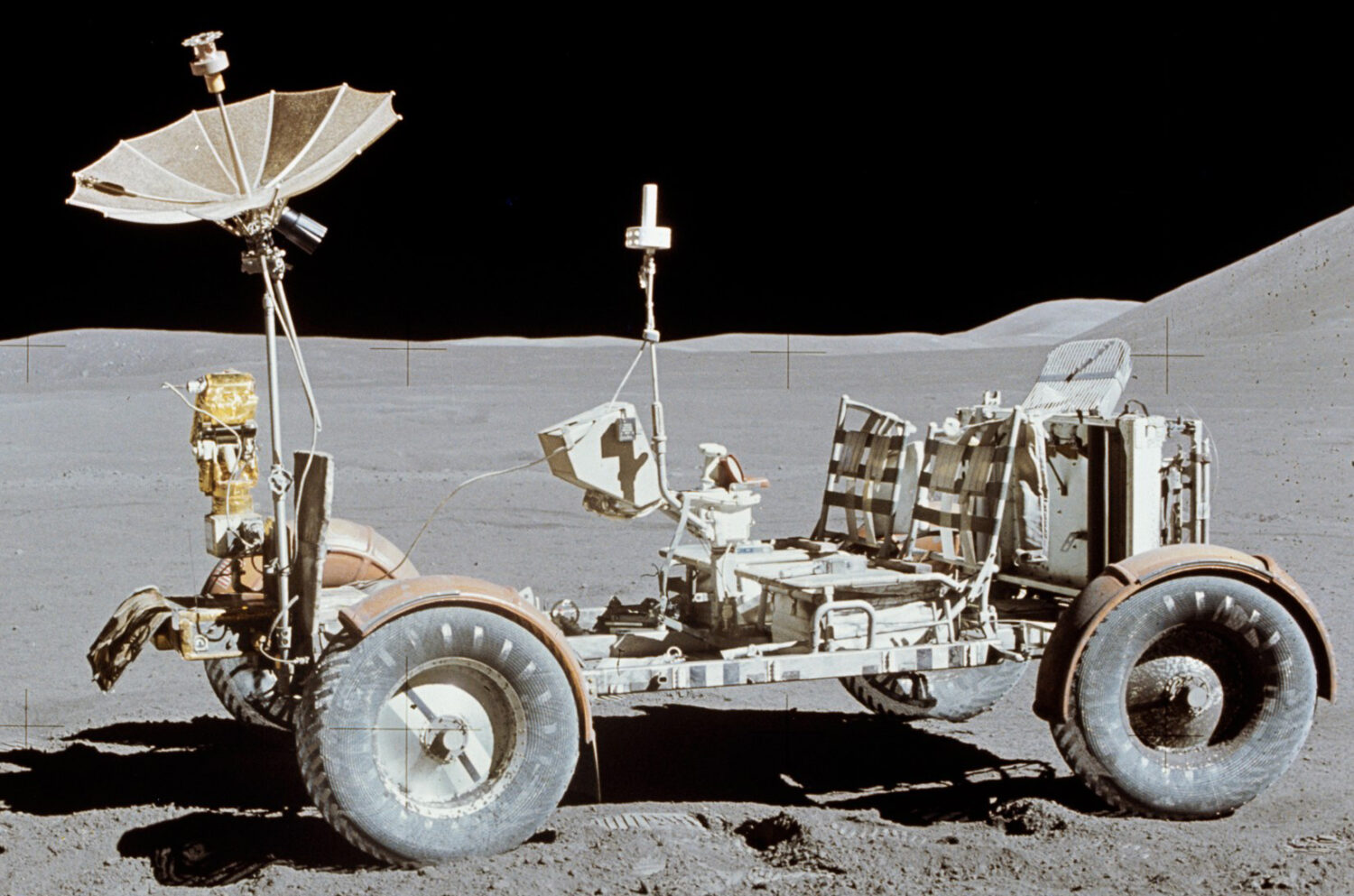

Many things contribute to the individual character of a car. Some models are super rare, being released in batches of dozens or custom jobs that are truly one of one. Some cars stand out because of where they’ve been, and the vehicle we’re profiling in this installment of Ride of Your Life definitely fits that description. Here’s a look at the design, legacy, and influence of the Lunar Rover used by astronauts in the Apollo Program to explore the lunar surface.

The engineering of the Lunar Rover, a vehicle designed for the Apollo missions to explore the Moon’s surface, was a marvel of innovation and problem-solving, tailored to operate in the harsh lunar environment. Engineers faced numerous challenges, including extreme temperature fluctuations, the Moon’s reduced gravity, and the need to transport the rover to the Moon compactly. The solution was a lightweight, foldable design that could be packed into a small space aboard the Lunar Module. Its frame was made from high-strength aluminum alloy to withstand the rigors of lunar terrain while minimizing weight.

Power was provided by batteries capable of operating in the cold vacuum of space, driving four independent electric motors—one for each wheel. The wheels themselves were a mesh design, made from zinc-coated piano wire, to provide traction on the lunar soil while being flexible enough to absorb shocks from the uneven terrain. Navigation was facilitated through a simple, yet effective, directional gyro system complemented by a speedometer, allowing astronauts to travel and explore significant distances from the Lunar Module.

Why Did We Need a Lunar Rover?

During the Apollo missions, the Lunar Rover, officially known as the Lunar Roving Vehicle (LRV), was used to greatly enhance the range of exploration and scientific capabilities of the astronauts on the Moon. Its introduction transformed lunar surface expeditions, allowing astronauts to travel much farther from the Lunar Module than was possible on foot, thereby significantly increasing the geographical area they could study and collect samples from.

The Lunar Rover enabled astronauts to carry more equipment and return more lunar soil and rock samples to Earth, enriching our understanding of the Moon’s composition, geological history, and surface environment. It was equipped with a variety of scientific instruments, including a television camera that provided live broadcasts to Earth, allowing scientists and the public alike to partake in the exploration of the lunar surface in real-time.

The rover was used for experiments such as the Lunar Surface Gravimeter and the Lunar Ranging Retro Reflector, which were designed to study the Moon’s gravitational field and measure the Earth-Moon distance precisely. The rover’s capability to traverse difficult terrain allowed the Apollo missions to conduct more comprehensive geological surveys, including the examination of craters, the lunar mare, and highlands, providing invaluable data that contributed to our understanding of lunar and planetary science.

In essence, the Lunar Rover was a critical tool for extending human reach and scientific inquiry on the lunar surface, marking a significant milestone in the history of space exploration.

The Lunar Rover was driven by astronauts during the Apollo 15, Apollo 16, and Apollo 17 missions to the Moon.

The Lunar Rover was designed with a top speed of about 8 miles per hour (about 13 kilometers per hour), though the actual speeds achieved during the missions were often lower, depending on the terrain and the caution exercised by the astronauts. Eugene Cernan, the last man to drive the Lunar Rover on Apollo 17, is noted for having reached speeds close to the vehicle’s maximum capability, playfully claiming the unofficial title of the “fastest human on the Moon.”

How to Drive on the Moon

Designing the Lunar Rover entailed overcoming a series of formidable challenges, necessitated by the moon’s harsh and unforgiving environment. One of the most significant hurdles was the moon’s extreme temperature variations, which could swing from -280 degrees Fahrenheit (-173 degrees Celsius) at night to 260 degrees Fahrenheit (127 degrees Celsius) during the day. This required the rover to be built with materials and electronic components that could withstand such fluctuations without degrading.

The moon’s reduced gravity, at only one-sixth of Earth’s, posed another challenge, affecting everything from the rover’s weight and structure to its mobility and the astronauts’ ability to control it. Engineers had to ensure the rover was lightweight yet durable enough to carry astronauts and their equipment across the lunar surface without toppling over or sinking into the lunar regolith.

The need to transport the rover to the moon in a compact form was also a considerable engineering feat. The rover had to be designed to fold into a small space aboard the Lunar Module and then be deployed and unfolded into a fully functional vehicle, a task that required innovative design solutions to ensure reliability and simplicity of operation under lunar conditions.

The lunar surface itself, covered with fine lunar dust that could adhere to and potentially clog or degrade mechanical systems, necessitated creating a design that minimized these risks. The development of wheels capable of navigating the loose lunar soil and craters without becoming entangled in the regolith was critical.

Assembling the Team

Addressing these challenges required a multidisciplinary approach, blending aerospace engineering, automotive design, and materials science, leading to the creation of a vehicle that could successfully operate under the moon’s unique conditions and contribute significantly to the Apollo missions’ exploration capabilities.

The engineering of the LRV, was a collaborative effort involving several different organizations composed of experts across various fields. The primary contractor for the design and development of the Lunar Rover was Boeing, a leading aerospace company. Boeing was responsible for the overall project management and integration of the rover’s systems.

To address the specific challenges of creating a vehicle that could operate on the lunar surface, Boeing partnered with General Motors’ Defense Research Laboratories, particularly the team led by Ferenc Pavlics. This collaboration brought together Boeing’s expertise in aerospace and General Motors’ experience in automotive engineering. Pavlics and his team at General Motors were instrumental in developing the rover’s mobility and wheel design, ensuring that it could navigate the Moon’s challenging terrain.

NASA’s Marshall Space Flight Center in Huntsville, Alabama, also played a critical role in overseeing the project, contributing technical expertise, and ensuring that the rover met the stringent requirements for space exploration. Engineers, scientists, and technicians from these organizations worked together to overcome the unique challenges of lunar exploration, resulting in a vehicle that significantly expanded the capabilities of astronauts during the Apollo 15, 16, and 17 missions.

This multidisciplinary approach, combining aerospace engineering, automotive design, and space science, was key to the Lunar Rover’s success, demonstrating the power of collaboration in overcoming the challenges of space exploration.

An Enduring Design

The design of the Lunar Rover’s tires was unique and innovative, specifically engineered to address the challenges of the lunar surface. Unlike traditional rubber tires used on Earth, the Lunar Rover’s tires were made from a woven mesh of zinc-coated piano wire, forming a flexible yet durable structure. This mesh design allowed the tires to conform to the irregularities of the lunar terrain, providing stability and traction while minimizing weight—a crucial consideration given the Moon’s lower gravity.

The absence of an atmosphere on the Moon meant that traditional pneumatic tires would not be suitable, prompting engineers to devise this novel solution. The wire mesh was supplemented with titanium treads, or “chevrons,” to enhance traction on the loose lunar soil and prevent the wheels from digging in. This design also allowed the tires to absorb shocks from traversing over rocks and craters, protecting the vehicle and its occupants from the jarring impacts associated with lunar exploration.

The open structure of the wire mesh minimized the accumulation of lunar dust, which could potentially clog or degrade mechanical systems. The innovative tire design of the Lunar Rover was a key factor in its ability to navigate the challenging lunar environment effectively, showcasing the ingenuity required to solve the unique problems of space exploration.

The Lunar Rover’s development and deployment to the Moon had a significant and lasting impact on automotive engineering and design of our vehicles here on Earth, primarily through the innovation and problem-solving approaches that were required to overcome the unique challenges of lunar exploration. Although the direct applications of its technologies were specialized for space exploration, the principles and innovations have influenced various aspects of terrestrial automotive design and engineering.

The use of lightweight, high-strength materials such as aluminum alloys in the Lunar Rover’s frame demonstrated the advantages of reducing vehicle weight without sacrificing strength and durability. This principle has been increasingly applied in the automotive industry to improve fuel efficiency and performance in cars and other vehicles.

The Lunar Rover was powered by batteries, making it one of the earliest examples of an electric vehicle (EV) operating under extreme conditions. This early adoption of electric propulsion has parallels with the modern automotive industry’s shift towards electric vehicles, highlighting the importance of battery technology and electric motors for sustainable transportation.

The innovative mesh tire design of the Lunar Rover, created to navigate the Moon’s soft and rugged terrain, has inspired research into non-pneumatic, airless tire technologies for use on Earth. These tires promise greater durability and resistance to punctures compared to traditional pneumatic tires.

The Lunar Rover’s suspension system was designed to handle the Moon’s uneven terrain, offering insights into adaptive and durable suspension designs. This has implications for developing vehicles that can efficiently navigate challenging terrains on Earth, particularly in off-road and military applications.

The capability to control the Lunar Rover remotely from Earth and the integration of autonomous features for navigation and operation have contributed to the advancement of autonomous vehicle technologies and remote control systems in terrestrial vehicles.

The overall approach to designing a vehicle that could be compactly stored, then deployed and operated on the lunar surface, has inspired engineers to think creatively about space utilization, modularity, and adaptability in vehicle design.

While the Lunar Rover’s direct technologies may not have been immediately transferrable to commercial vehicles, the engineering challenges it addressed and the solutions developed have certainly influenced modern automotive engineering and design philosophies, pushing the envelope of what is possible in vehicle technology and innovation.