Understanding the basics of how car engines work is crucial for anyone who drives or owns a vehicle. By gaining a basic knowledge of engine operation, car owners can better comprehend the advice given by mechanics, make informed decisions about car maintenance, and recognize early signs of engine trouble. This foundational knowledge helps in maintaining the vehicle’s longevity and performance, ensuring that your car remains reliable on the road.

Car Engine Components

The Engine Block and Cylinders

The engine block, often crafted from durable aluminum or cast iron, serves as the heart of an automobile’s engine. It provides the main structure for housing the cylinders and other essential components like pistons, the crankshaft, and, in some designs, the camshaft. The choice of material plays a crucial role in the engine block’s performance, with aluminum offering lighter weight and efficient heat dissipation, while cast iron provides high durability and resistance to wear. Inside this robust block, the cylinders operate as individual chambers where the fuel combustion process occurs, powering the vehicle. Engine blocks are engineered to withstand extreme temperatures and pressures generated during combustion, which can affect the overall performance and lifespan of the engine. To achieve this, manufacturers prioritize precision engineering and advanced materials that can handle these rigorous demands, ensuring the engine runs efficiently for thousands of miles.

At the center of the combustion process are the cylinders, which are meticulously integrated within the engine block to create an optimal environment for fuel ignition. Each cylinder houses a piston, a component that moves up and down in response to fuel combustion, creating the compression required to ignite the fuel and release energy. This movement of the piston is precisely timed with other engine functions, coordinated by components like the crankshaft and camshaft, which further synchronize the engine’s operation. The design and configuration of these cylinders, whether in a straight-line (inline), V-shaped, or horizontally opposed arrangement, impact the engine’s power output, efficiency, and performance characteristics.

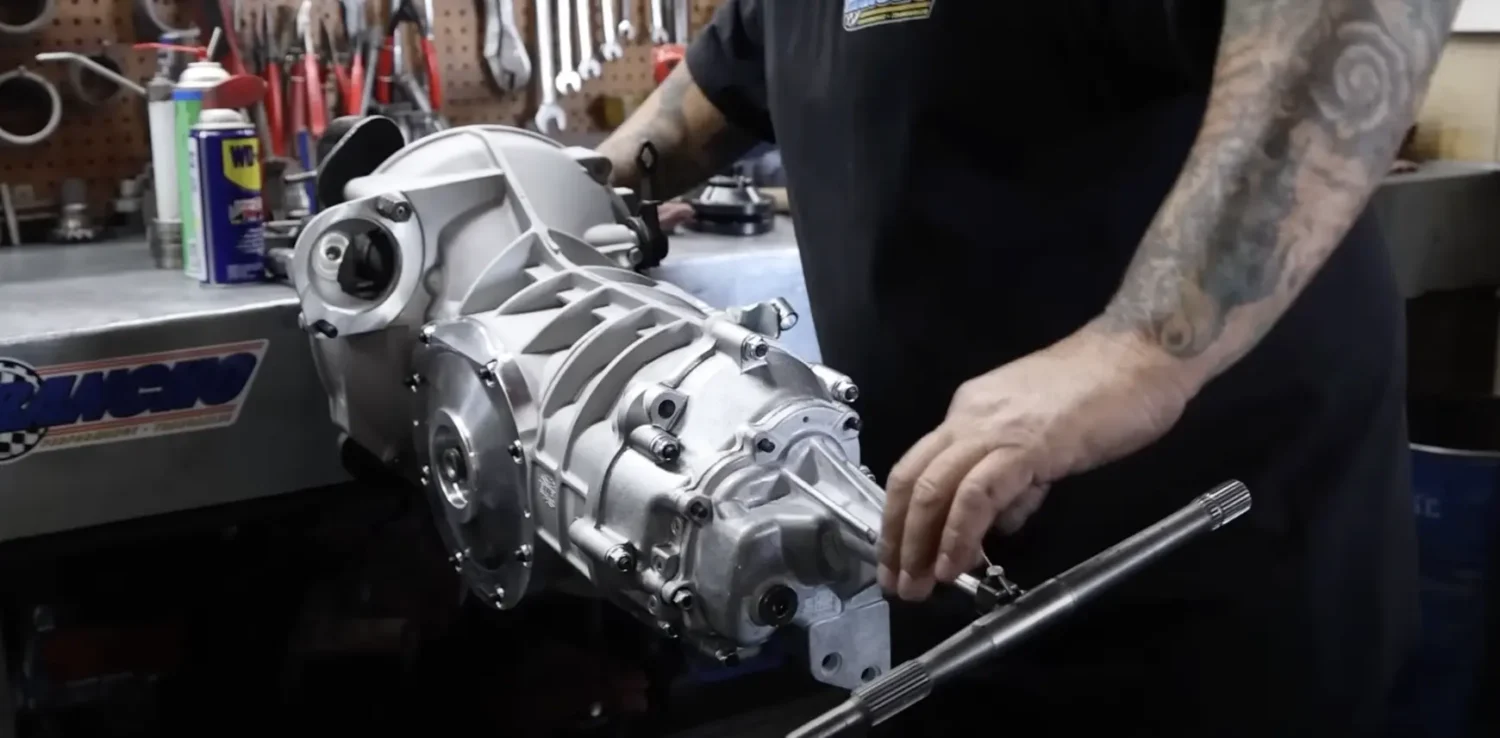

Pistons and Crankshaft

Located within the engine cylinders, they move up and down, driven by the energy from the combustion of the air-fuel mixture. This linear motion of the pistons is transformed into rotational motion by the crankshaft. The crankshaft then transmits this rotational motion to the car’s transmission, and eventually, to the wheels. Such conversion is fundamental to how a car moves. The efficiency and smoothness of this motion transfer are critical for optimal engine performance.

Air Intake System

The car engine air intake system is crucial for its performance. It regulates the air that enters the engine for the combustion of fuel. A well-functioning system ensures that the engine receives the right amount of air, mixed with fuel, to generate power. This system includes filters to keep out contaminants and ensure that only clean air enters the engine, which helps maintain efficient combustion and reduces wear and tear on engine components.

Timing Belt

A crucial part of the engine’s internal mechanism, the timing belt plays a significant role in ensuring that the engine’s moving parts, like the pistons and valves, operate in sync. It helps maintain the timing of the engine’s camshaft and crankshaft so that the valves open and close at the correct times during the intake and exhaust strokes. A malfunctioning timing belt can lead to engine misfires, poor efficiency, or even severe engine damage.

Types of Car Engines

Inline Engines

Often found in smaller vehicles, these engines feature a simple design with all engine cylinders aligned in a single row. This configuration allows for a more compact engine bay and easier maintenance. Inline engines are known for their smooth operation due to the linear arrangement of cylinders, which balances the engine effectively. This type of engine usually offers better fuel and air mix in car engines, enhancing car engine fuel efficiency. The simplicity of the inline engine makes it one of the most common and reliable engine types available.

V-Shaped Engines

V-shaped engines are characterized by their unique arrangement where the cylinders are set in two rows angled in a ‘V’ formation. This setup allows them to be more compact, fitting into spaces where an inline engine might not, making them ideal for larger, performance-focused vehicles like sports cars. The V-shape design supports more cylinders, which can increase power and car engine displacement without significantly enlarging the engine’s footprint. V-engines are celebrated for their robust performance and ability to generate more horsepower and torque.

Flat Engines

Also called boxer engines, these feature cylinders that are horizontally opposed, lying flat on either side of the crankshaft. This architecture gives vehicles a lower center of gravity, which enhances stability and balance, particularly in sharp turns. Common in sports and luxury cars, flat engines can provide a smooth ride with reduced vibration due to the opposite cylinders balancing each other out. They also contribute to a vehicle’s aerodynamic profile by allowing a lower overall vehicle height.

Cylinder Count and Engine Displacement

The number of cylinders in an engine can greatly affect both its performance and efficiency. Typically, more cylinders mean more power but also greater fuel consumption. Engine displacement, measured in liters or cubic centimeters, refers to the total volume of air/fuel mixture an engine can suck in during one complete engine cycle. Generally, a higher displacement indicates a more powerful engine, but it can also result in lower fuel efficiency.

Combustion Process in Car Engines

Mixing Fuel and Air for Optimal Combustion

The process of combustion in car engines starts with the precise mixing of air and fuel, a critical step for efficient engine operation. This mixture ensures that the engine runs smoothly and powerfully. The ratio of air to fuel can greatly influence engine performance; too much air or too little fuel can lead to poor combustion and decreased efficiency. Modern engines utilize advanced technologies like fuel injection systems to optimize this mix, enhancing the overall car engine fuel efficiency and reducing wasteful emissions.

The Role of Spark Plugs

By delivering an electric spark to ignite the air-fuel mixture within the cylinders, spark plugs must fire at just the right moment to ensure efficient combustion. This precise timing is crucial for maintaining an engine’s performance and longevity. Here’s how spark plugs impact the engine’s operation:

- Ignition: When the spark plug fires, it triggers a controlled explosion, which powers the engine’s pistons and ultimately moves the vehicle. This spark must be strong and consistent to initiate combustion every time, even under extreme temperatures or pressures. Reliable ignition from high-quality spark plugs ensures the engine starts smoothly, performs well under varying conditions, and provides dependable power output. This process is foundational to the operation of any gasoline engine, making spark plugs a crucial component for vehicle reliability and performance.

- Timing: They must fire at just the right moment to ignite the air-fuel mixture when it is most compressed within the cylinder. This precise timing is necessary to avoid issues like “knocking,” which can damage components of a car’s engine block and reduce fuel efficiency. Properly timed spark plugs ensure the combustion process is optimized, allowing the engine to harness maximum power from each ignition cycle. Accurate timing also enhances the engine’s responsiveness, creating smoother acceleration and a more enjoyable driving experience.

- Efficiency: When the air-fuel mixture is ignited at the optimal time, it burns more completely, ensuring that all the energy from the fuel is utilized effectively. This complete combustion minimizes wasted fuel, allowing the vehicle to achieve better mileage per gallon and reducing overall fuel costs. Spark plugs that fire consistently and with the right intensity support the engine’s ability to run smoothly and economically, helping drivers save on fuel expenses while also maintaining vehicle performance over the long term.

- Emissions: In addition to efficiency, spark plugs play a role in reducing vehicle emissions. When the spark plug ignites the air-fuel mixture properly, it ensures a complete burn, which decreases the number of unburned hydrocarbons and other pollutants released into the atmosphere. Efficient combustion lowers harmful emissions like carbon monoxide, hydrocarbons, and nitrogen oxides, which are byproducts of incomplete fuel burning.

Each aspect of a gasoline engine’s performance—from ignition and timing to fuel efficiency and emissions—relies on the spark plugs’ ability to function optimally. This small component plays a significant role in overall vehicle performance and longevity, making it a crucial focus for both car enthusiasts and everyday drivers.

Diesel Engines and Compression Ignition

Unlike gasoline engines that use spark plugs for igniting the air-fuel mix, diesel engines rely on compression ignition. This process involves compressing air to high pressures and temperatures so that when the diesel fuel is injected, it ignites spontaneously. Diesel’s high efficiency comes from its ability to operate at a higher compression ratio, leading to better energy extraction from the fuel. The nature of compression ignition also contributes to diesel engines’ reputation for higher torque and durability, particularly under heavy load conditions.

Differences Between Petrol and Diesel Engines

Fuel Injection and Ignition Differences

The method of fuel injection is another point of distinction. Petrol engines typically use either port fuel injection or direct injection, where fuel is sprayed into the intake manifold or directly into the combustion chamber, respectively. Diesel engines, however, exclusively use direct injection, where diesel is injected directly into the compressed, hot air in the combustion chamber. This method allows for greater precision in controlling the fuel-air mixture and timing of combustion, which enhances the efficiency and power output of diesel engines.

Performance and Efficiency Comparisons

Petrol engines are generally lighter and can achieve higher RPMs, which translates to a smoother and quicker response when accelerating. However, diesel engines excel in generating higher torque and provide superior fuel economy, making them ideal for heavy-duty vehicles and long-distance travel due to their lower fuel consumption. Knowing how internal combustion engines work also contributes to these differences, as diesels typically run leaner mixes that burn less fuel.

Maintenance Considerations for Each Type

Due to their different mechanics, diesel and gasoline engines require separate car engine maintenance. Diesel engines, for instance, require more robust oil and more frequent changes of the air and fuel filters. They are also more sensitive to poor fuel quality. Petrol engines, while generally requiring less rigorous maintenance schedules, are more sensitive to issues like the buildup of deposits in the fuel system, necessitating occasional fuel system cleaning and more frequent spark plug replacement.

Common Car Engine Problems and Warning Signs

Recognizing Overheating

This condition can stem from various factors, each indicating specific mechanical issues that require immediate attention. Recognizing the symptoms and understanding the root causes of overheating can help prevent further damage and maintain a reliable vehicle. Here are the primary causes of engine overheating:

- Coolant System Failures: The coolant system plays a critical role in regulating engine temperature by circulating coolant through the engine and radiator. However, if there’s a leak in the radiator, a faulty water pump, or clogged hoses, coolant cannot flow properly, causing the engine to overheat. Leaks can be hard to detect initially, but symptoms like coolant puddles under the car or the smell of antifreeze are tell-tale signs. Reduced coolant levels can lead to localized hotspots within the engine, which strain internal components.

- Thermostat Malfunction: The thermostat controls the flow of coolant between the engine and radiator, helping the engine reach and maintain an optimal temperature. If the thermostat becomes stuck in the closed position, it blocks the flow of coolant to the radiator, preventing it from cooling down. This blockage quickly leads to an increase in engine temperature, as heat accumulates without relief. A malfunctioning thermostat can go unnoticed until it leads to a breakdown, often triggered by a rise in temperature or the dashboard warning light.

- Radiator Issues: A radiator that is damaged, clogged with debris, or suffering from rust buildup cannot effectively cool the coolant, leading to overheating. Restricted coolant flow due to a clogged radiator causes the engine to retain excess heat, resulting in higher engine temperatures, particularly in hot weather or during heavy driving conditions.

- Poor Coolant Condition: An aged or dirty coolant lacks the thermal properties needed to absorb and transfer heat efficiently, compromising the cooling system’s performance. Additionally, if the coolant is too diluted with water, its boiling point lowers, increasing the risk of overheating, especially under high engine loads.

Proactive maintenance, such as checking the coolant level, inspecting for leaks, and servicing the radiator, helps keep the engine cool. Regularly attending to these components allows the car engine cooling system to perform effectively, ensuring the engine operates smoothly and reliably, even in challenging conditions.

Misfires and Reduced Engine Power

Engine misfires can be alarming as they significantly affect vehicle performance and efficiency. A misfire occurs when the engine fails to ignite the fuel-air mixture in one of the cylinders properly. This can result from a variety of issues, including worn spark plugs, clogged fuel injectors, or faulty ignition coils. Symptoms of a misfire include a rough idle, decreased power, and an increase in exhaust emissions. Diagnosing and addressing misfires early is crucial to prevent further engine damage and restore smooth operation.

By adhering to these car engine fuel efficiency tips and understanding the function of different engine types and components, drivers can significantly improve the lifespan and efficiency of their vehicles. Being proactive in car care saves on costly repairs and ensures that the vehicle remains a reliable companion on the road.