There’s something about tinkering with the impossible that draws us in, and this experiment with a dead car battery was no exception. For years, I’ve been curious about rejuvenating sulfated lead-acid batteries by zapping them with a stick welder. Could this work? Would it explode? Well, I finally decided to try it—and the results surprised even me.

A Few Words of Warning

Before we dive in, let me lay down some ground rules. First off, don’t try this indoors. Batteries release flammable gases, and if they go “poof,” you don’t want to be trapped in an enclosed space. I had to work inside for filming reasons, but trust me: this is backyard science, not a garage project. Always wear eye protection, keep a water source nearby, and don’t skimp on safety.

Also, not every dead battery is salvageable. Some fail because of internal breaks between the plates or connections, and no amount of zapping will bring them back. Others die due to sulfation, a natural crusting over of the plates that happens as batteries age or sit unused. Sulfation blocks the reaction between the acid and the lead, effectively killing the battery. That’s what I was tackling here.

The Stick Welder Method

The method I used is based on what professional battery reconditioners do: overcharging the battery in cycles. Unlike a standard 12-volt charger, which can’t break through the sulfation, a stick welder delivers a high-amperage current that can physically knock some of the crust off the plates. Sounds wild, right? Let’s see how it went.

The Battery in Question

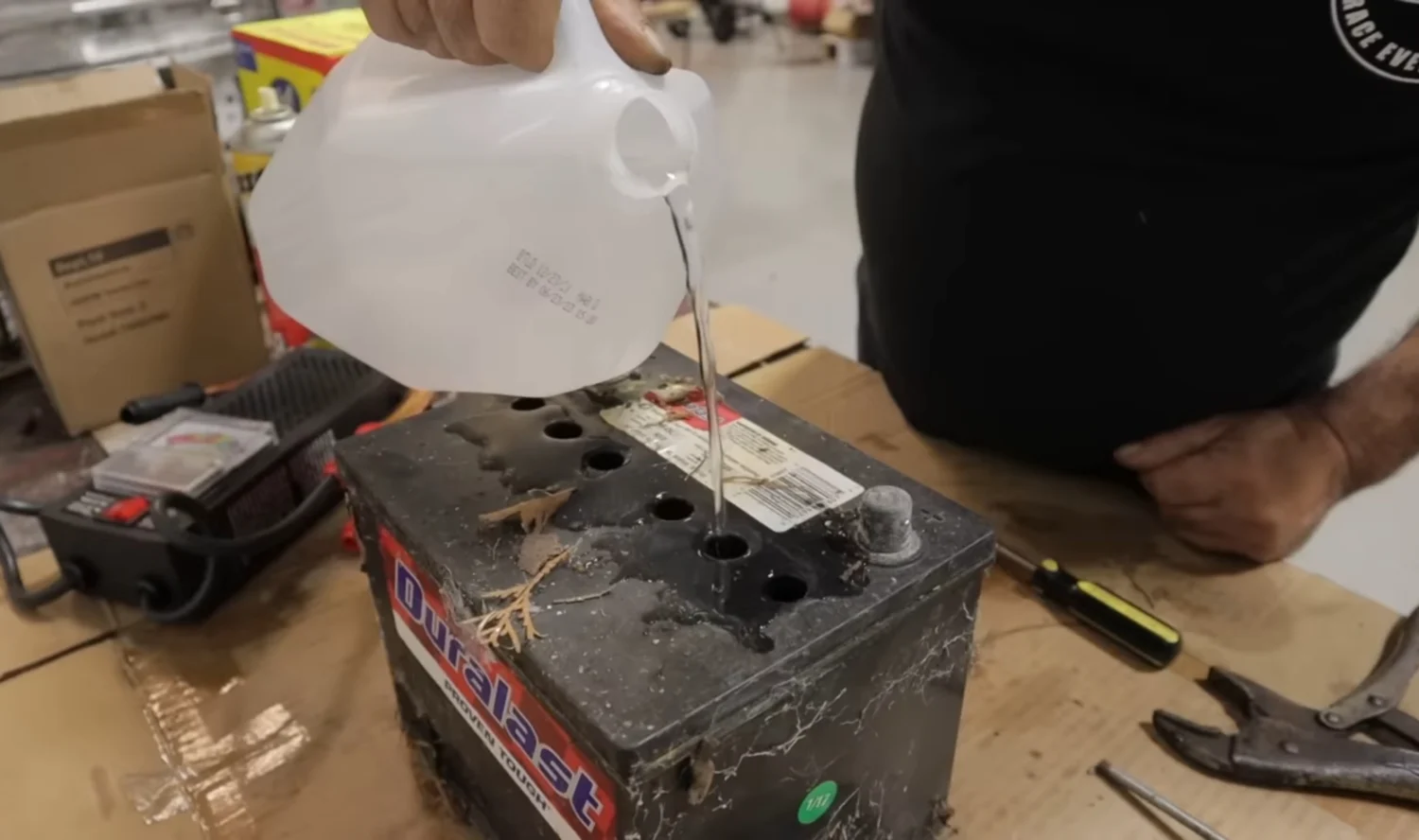

For this experiment, I grabbed a seriously dead battery that had been sitting on the side of my house for years. Covered in spiderwebs and debris, it was about as lifeless as a battery could get. Step one was to check the water levels. If you try this at home (again, outdoors, please), always use distilled water to top off the cells. Tap water contains minerals that can interfere with the chemical reaction.

Once the battery was filled to spec, I wiped it down and prepared for the first zap.

Getting Started

Using a Harbor Freight stick welder, I connected the ground clamp to the battery’s negative terminal and the positive clamp to a threaded rod secured with a vice grip. I started the welder at a low amperage, around 50 amps, and waited for signs of bubbling in the cells. Sure enough, the acid began to boil—proof that the current was doing its job.

As I increased the amperage to 85, then 100, the bubbling intensified. One cell, which I’d overfilled slightly, started to foam and release a cloudy substance. My guess? That was sulfation being blown off the plates. The process was messy, smelly, and honestly, a little nerve-wracking, but I was hooked.

The Results

After letting the battery bubble for about five minutes, I turned off the welder and let it cool down for 15 minutes. Then I repeated the process twice more, gradually increasing the amperage to 140 amps in the final cycle. Each time, the bubbling got more intense, and by the end, the battery was nearly hot to the touch.

Curious about the outcome, I hooked up a load tester. The results? A solid 12 volts, with over 600 amps on the load test—better than I expected for a battery that had been sitting dead for three years. It was holding steady, and for now, it seemed like the experiment was a success.

The Big Question: Is It Permanent?

Here’s the catch: I can’t say for sure how long this fix will last. The battery could hold up for weeks, or it might revert to its sulfated state after a few days. I’ll be testing it in a car over the next week to see if the rejuvenation holds. But even if this turns out to be a temporary fix, it’s a fascinating proof of concept—and it’s got me thinking.

The Potential for a Side Hustle

If this method works consistently, it could be the ultimate DIY side hustle. With a cheap stick welder and a little patience, you could recondition old batteries and sell them at a tidy profit. Imagine the possibilities: saving batteries from the landfill, helping people on a budget, and making some extra cash in the process.

This experiment was as educational as it was thrilling. It’s not for everyone—there’s some risk involved—but it’s a great example of old-school ingenuity meeting modern curiosity. If you’re going to try this, follow every safety precaution I mentioned and be prepared for a few surprises along the way.

Check out the full video on my YouTube Uncle Tony’s Garage. And while you’re there, subscribe for more DIY experiments, classic car builds, and budget-friendly hot-rodding tips. Let’s keep the spirit of old-school wrenching alive!