When I first started AP EV Systems in Bellingham, Washington, my mission was simple: to blend the elegance of classic cars with modern electric technology. One of our most exciting projects was converting a 1983 Porsche 911 SC into a more powerful, sustainable version of itself.

Why Power Matters: Enhancing the Driving Experience

To bring this classic Porsche into the modern age, we knew we had to upgrade its power and performance. The goal was to maintain the car’s soul while making it faster, stronger, and more practical for everyday use. Here’s what we did:

- Increased horsepower from the original 188 to an impressive 320 using a 73 kWh battery.

- Boosted torque to 370 ft-lb for improved responsiveness and handling.

- Equipped the car with a 250-mile driving range, making it perfect for both weekend drives and daily commutes.

Preserving the Feel: Structural Upgrades

The conversion isn’t just about adding an electric motor; it’s about improving the car’s structural integrity and maintaining that classic driving experience. To achieve this balance, we made several key upgrades:

- Designed custom components through 3D scanning and CAD modeling to perfectly integrate with the Porsche’s original framework.

- Built carbon fiber subframes to reduce weight and improve the car’s strength.

- Enhanced the vehicle’s overall structure, ensuring a smoother and more dynamic driving experience.

Why We Chose Carbon Fiber

Using carbon fiber wasn’t just an aesthetic decision – it was about performance. This material is essential for making the car lighter and more agile while still maintaining strength. Here’s how we used it:

- Created carbon fiber subframes that are significantly lighter and stronger than traditional steel.

- Manufactured the components in-house for precise integration with the car’s design.

- Improved torsional rigidity, giving the car better handling and performance.

Prioritizing Safety in Our Conversions

When working with high-powered electric systems, safety is always a top priority. We wanted to ensure that our battery packs were both powerful and protected. Here’s how we approached safety:

- Encased the battery packs in multiple layers of protection: glass fiber for chemical and temperature resistance, Kevlar for impact protection, and carbon fiber for added rigidity.

- Designed the battery system to withstand high temperatures and potential impacts.

- Ensured the vehicle remains safe on the road, even in extreme conditions.

Maintaining the Classic Feel: Keeping the Original Gearbox

One of the best parts about driving a classic Porsche is the manual transmission. Instead of replacing it with a fully electric setup, we wanted to keep that iconic feel while incorporating the benefits of electric power. To do this, we:

- Retained the original five-speed manual transaxle to preserve the Porsche’s classic driving experience.

- Developed a custom vehicle control unit to manage the power and torque output through the manual gearbox.

- Combined modern electric efficiency with the nostalgic feel of a classic Porsche.

Making Installation Easy: Turnkey Solutions

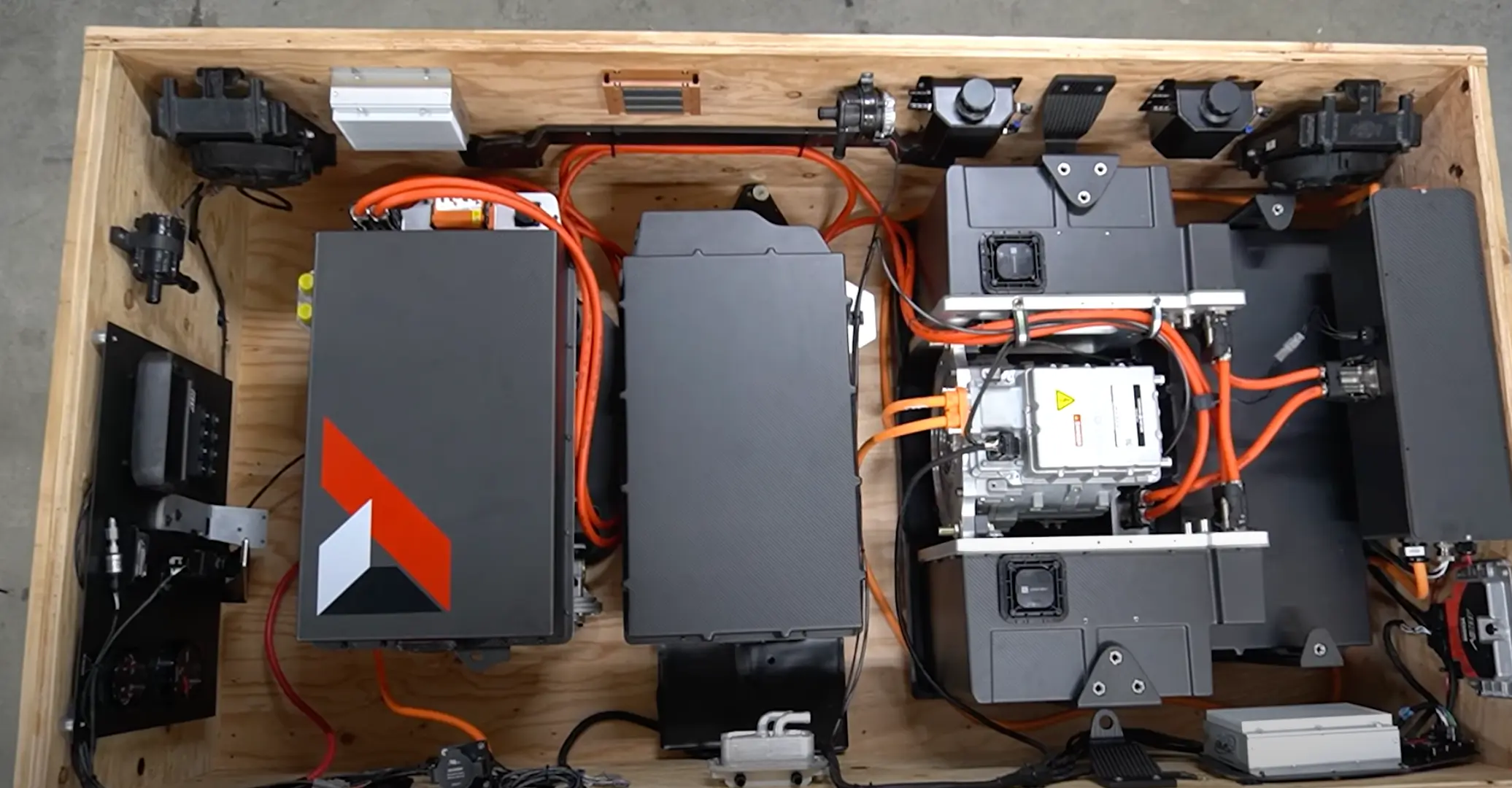

For our customers, we wanted to offer a solution that wouldn’t keep their cars in the shop for weeks. Our conversion kit was designed to be easy to install, without sacrificing performance. Here’s what our kit includes:

- A comprehensive three-day installation process that ensures a quick turnaround.

- Pre-installed components on carbon fiber subframes for ease of assembly.

- Pre-tested systems that ensure everything works reliably once installed.

Blending Classic Craftsmanship with Modern Technology

At AP EV Systems, our mission is to keep the spirit of classic cars alive while pushing them into the future with sustainable, cutting-edge technology. This project is a prime example of how we’re doing just that.